The Purpose and Function of Globe Valves in Industrial Applications

Table of Contents

ToggleIntroduction

Globe valves are essential components in fluid control systems. What is the purpose of a globe valve? These valves are designed to regulate and control the flow of a fluid in a pipeline. They do so by using a movable disk to throttle the flow, making them ideal for applications that require precise control over the fluid flow rate. Understanding the purpose and function of globe valves is crucial for ensuring the efficient operation of industrial and commercial fluid systems.

Understanding Globe Valves

Globe valves are essential components in various industrial applications, offering precise control over fluid flow. Understanding the functionality and purpose of these valves is crucial for optimizing their performance and ensuring reliable operation.

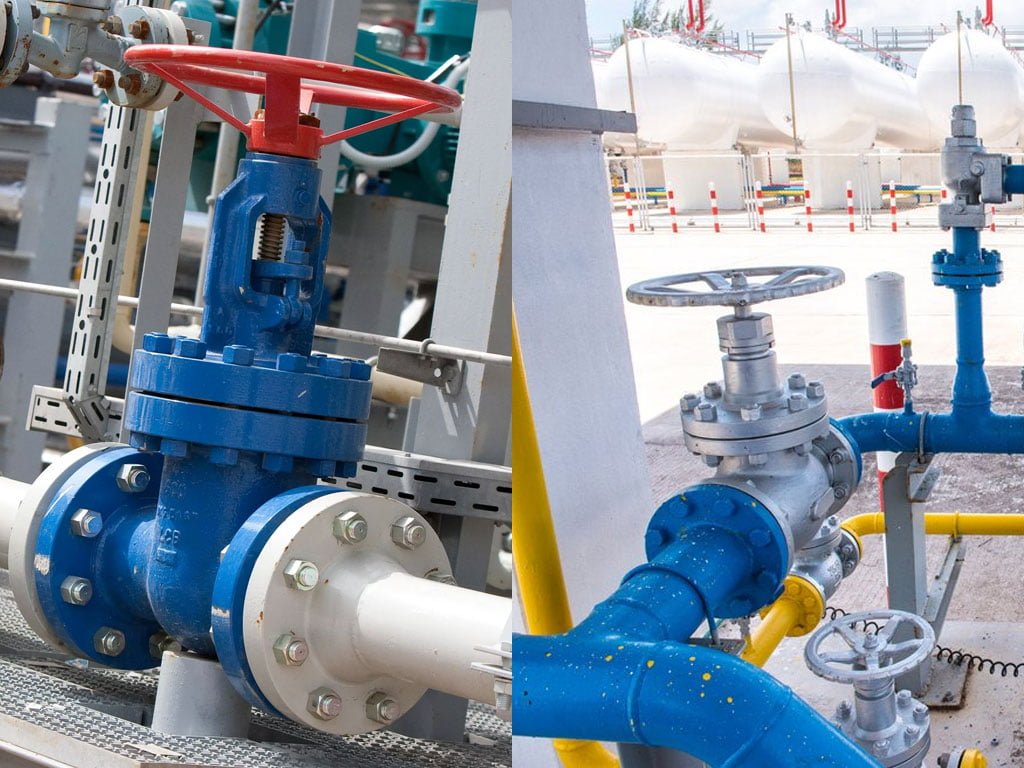

What are Globe Valves?

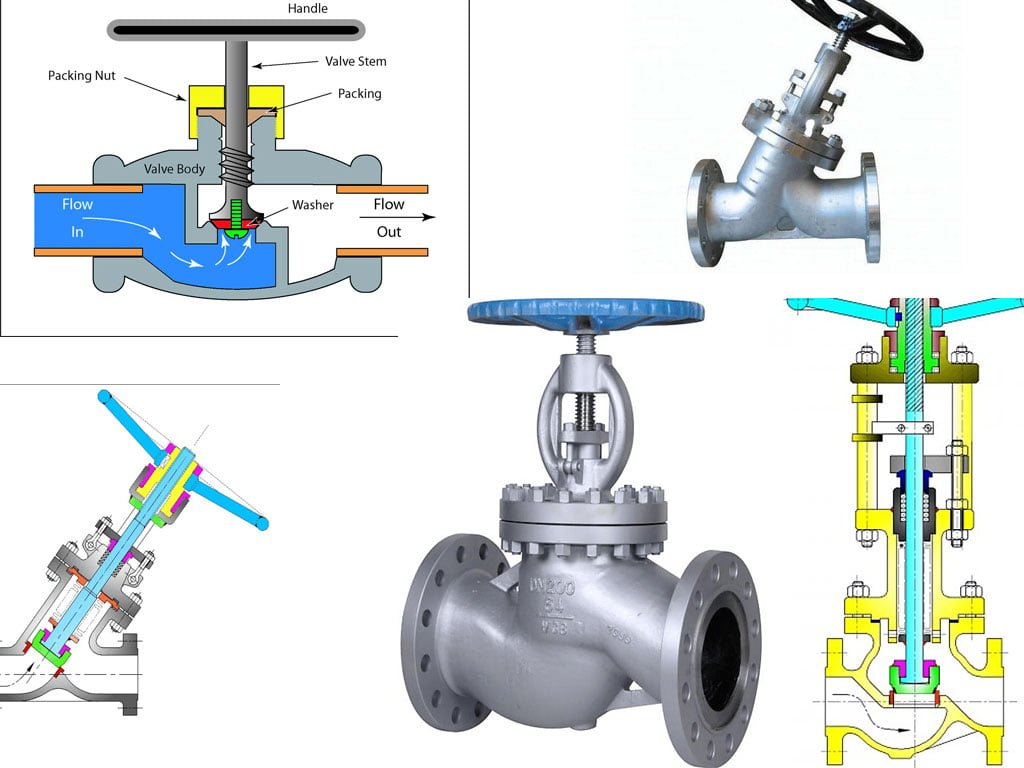

Globe valves are linear motion valves that are used to start, stop, and regulate the flow of a fluid within a pipeline. They are characterized by a spherical body shape with an internal baffle, creating a seat and a plug that moves in a perpendicular direction to the flow, effectively shutting off the flow. This design enables globe valves to provide accurate flow control, making them suitable for throttling applications.

How Do Globe Valves Work?

Globe valves operate by raising or lowering the internal plug to modulate the flow of fluid. When the handwheel or actuator is turned, the plug moves against the flow, either opening or closing the valve. This linear motion allows for precise adjustments, making globe valves ideal for applications where fine control over flow rate and pressure are necessary. The configuration of the internal components also enables globe valves to provide a tight shutoff, minimizing leakage when fully closed.

Globe valves play a critical role in regulating flow and pressure in pipelines, offering versatility and reliability in various industrial settings. Understanding their design and operation is fundamental for maximizing their efficiency and ensuring optimal performance.

Main Functions of Globe Valves

Globe valves are essential components in various industries, offering a range of functions to control the flow of fluids within a system.

Regulating Flow: Globe valves are designed to regulate the flow of fluids by adjusting the position of the valve disc in relation to the seat. This allows for precise control over the rate of flow through the valve.

Throttling: One of the primary functions of globe valves is throttling, which involves controlling the flow of a fluid to achieve the desired level. This is particularly useful in applications where precise flow control is critical.

Shutting Off Flow: Globe valves are capable of completely shutting off the flow of fluids when necessary. By fully closing the valve, the passage of fluid is blocked, providing an effective means of isolating sections of a system.

Pressure Regulation: These valves are adept at regulating pressure within a system. By adjusting the position of the valve disc, the resistance to flow can be modified, thereby influencing the pressure levels within the system.

Directional Flow Control: Globe valves can be utilized to control the direction of flow within a system. By configuring the valve appropriately, the flow of fluid can be directed as required for optimal system performance.

Diverse Applications: Globe valves find applications in a wide range of industries, including oil and gas, petrochemical, power generation, and water treatment. Their multifaceted functions make them indispensable in numerous industrial processes.

In conclusion, globe valves play a pivotal role in regulating, throttling, shutting off flow, and controlling pressure and direction within fluid systems across various industries. Understanding the diverse functions of these valves is crucial for ensuring efficient and reliable operation in industrial processes.

Purpose of Globe Valves

Controlling Flow and Pressure

Globe valves are designed to control the flow and pressure of a fluid within a pipeline. By adjusting the position of the valve stem, the flow of the fluid can be precisely regulated, allowing for optimal control over the pressure within the system. This feature is particularly useful in applications where a high degree of pressure regulation is required, such as in industrial processes or fluid distribution systems.

Regulating Flow Rate

Another key purpose of globe valves is to regulate the flow rate of the fluid passing through the system. The design of the valve, with its disk and seat arrangement, allows for fine-tuned adjustments to the flow, providing operators with the ability to manage the rate at which the fluid moves through the pipeline. This functionality is essential in scenarios where variations in flow rate can impact the efficiency and safety of the overall system.

Shut-Off Function

Globe valves also serve the critical function of providing a reliable shut-off mechanism. When the valve is fully closed, it creates a tight seal that prevents the passage of fluid through the pipeline. This shut-off capability is crucial in situations where it is necessary to stop the flow of the fluid completely, such as during maintenance activities or in the event of an emergency. The robust shut-off function of globe valves ensures that the system can be safely and effectively isolated when needed.

By fulfilling these essential roles, globe valves play a vital part in maintaining the optimal operation and safety of fluid control systems across a wide range of industries.

Industrial and Commercial Applications

Use in Power Plants

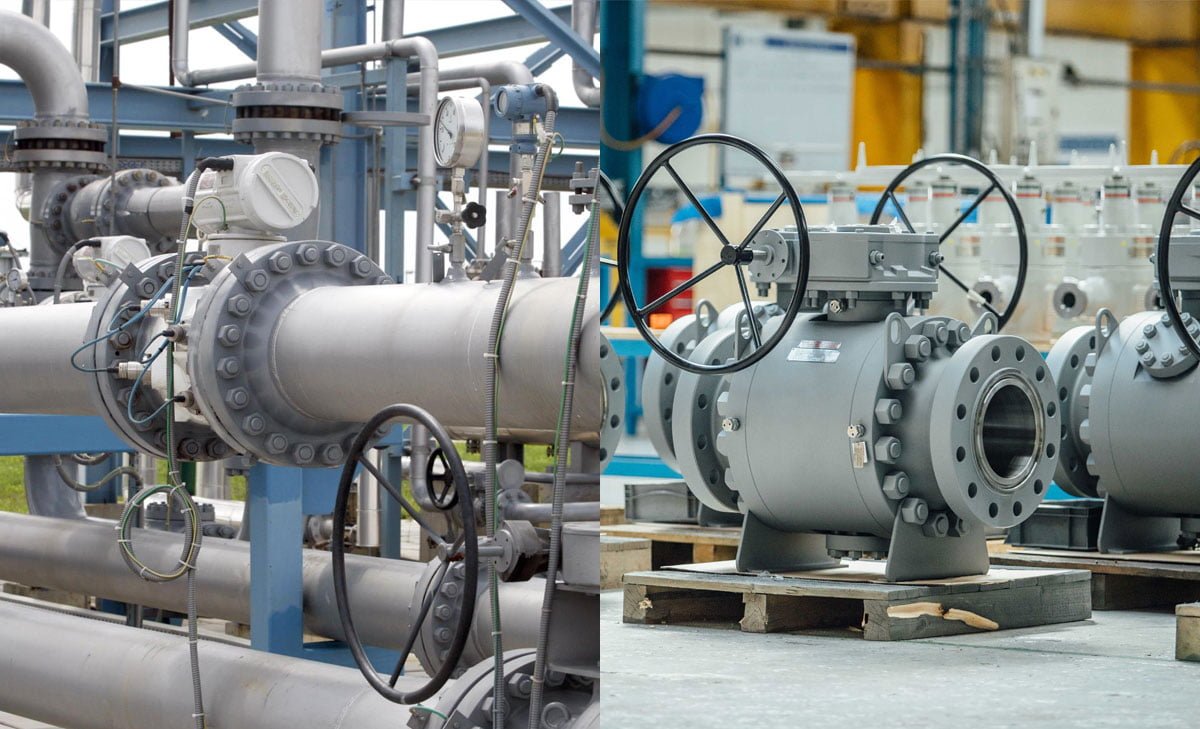

Globe valves play a critical role in power plants, regulating and controlling the flow of various fluids and gases such as water, steam, and fuel. These valves are strategically positioned within power plant systems to manage the flow and pressure, ensuring optimal energy production and operational efficiency. Their ability to throttle and modulate the flow makes them indispensable in power generation processes, where precise control is essential for safe and effective power output.

Role in Oil and Gas Industry

In the oil and gas industry, globe valves are vital components in the transportation, refining, and processing of crude oil and natural gas. Whether it’s regulating the flow of petroleum or modulating the pressure of natural gas, these valves provide reliable performance under high-pressure and high-temperature conditions. Their ability to handle a wide range of operating pressures and temperatures makes them essential for ensuring safety, efficiency, and environmental compliance in oil and gas operations.

Applications in HVAC Systems

Globe valves are widely used in heating, ventilation, and air conditioning (HVAC) systems to control the flow of hot water, chilled water, and steam. By precisely regulating the flow of these fluids, these valves help maintain optimal temperature levels within commercial and industrial buildings. Whether it’s managing the heating or cooling process, globe valves contribute to energy efficiency and occupant comfort, making them indispensable components in HVAC systems.

Advantages of Globe Valves

Precise Flow Control

Globe valves offer precise control over the flow of liquids due to their linear motion. The disc of the valve can be adjusted to regulate the flow rate, making it an ideal choice for applications that require accurate flow control, such as in water treatment plants or industrial processes.

Versatility in Operation

These valves can be used in a wide range of applications and are suitable for both high and low-pressure systems. Their versatility makes them a popular choice in industries such as oil and gas, pharmaceuticals, and chemical processing.

Reliable Shut-Off Capability

Globe valves provide a reliable shut-off capability, effectively stopping the flow of fluid when required. This feature is crucial in preventing leaks and ensuring safety in various industrial settings. The design of the valve allows for a tight seal, minimizing the risk of leakage.

Conclusion

In conclusion, the purpose of a globe valve is to regulate or stop the flow of a liquid or gas in a pipeline. By using a movable disk or plug, the valve can control the flow rate and pressure, making it an essential component in various industries such as oil and gas, water treatment, and manufacturing. With its ability to provide precise flow control, the globe valve plays a crucial role in ensuring the efficiency and safety of industrial processes.