Gate Valve Repair: Everything You Need to Know

Table of Contents

ToggleThe Ultimate Guide to Gate Valve Repair

Are you experiencing issues with a malfunctioning gate valve? Whether you are dealing with a leaking gate valve or facing any other problem, it is crucial to understand the ins and outs of gate valve repair. This comprehensive guide is designed to provide you with all the essential information you need to effectively address gate valve issues. From understanding the common problems to learning the step-by-step repair process, this cornerstone content will serve as your go-to resource for mastering gate valve repair.

Understanding Gate Valves

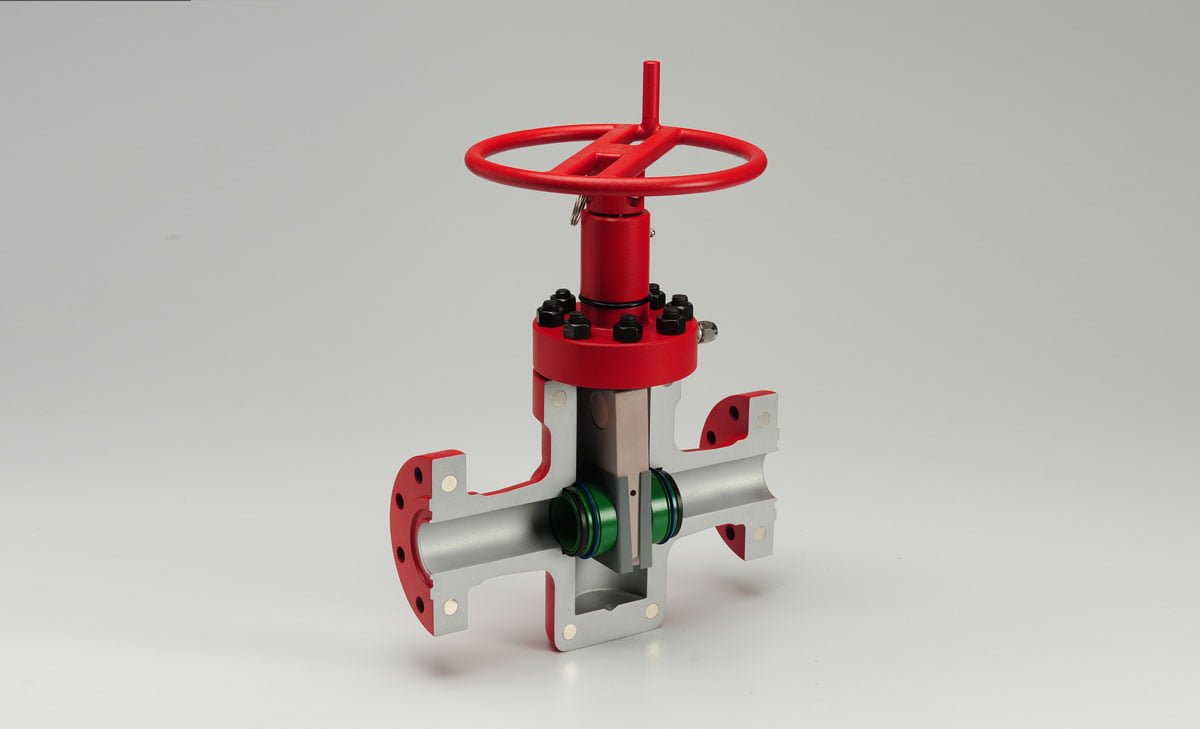

A gate valve is a control valve that either permits unobstructed flow of fluid or completely stops the flow. Its primary advantage is the straight-through unobstructed passageway, minimizing pressure loss. The unobstructed bore also facilitates pipe cleaning procedures with the passage of a pig. However, gate valves are slower than quarter-turn valves and are ideally used in fully open or closed positions, not for flow regulation. They are also referred to as sluice gate valves.

Definition and Function

A gate valve symbol typically consists of two triangles pointing toward the center of a vertical line. This symbol is commonly used in piping and instrumentation diagrams (P&IDs). The gate valve comprises seven main parts: handwheel, stem, gasket, bonnet, valve body, flange, and gate. The handwheel is turned to move the gate up or down on the stem via threads, opening or closing the valve. Gate valves require multiple 360° turns to fully open or close.

Types of Gate Valves

Gate valves are available in different designs to accommodate various applications, although the main function of the gate valve parts remains the same. Common connection types include flanged gate valves and threaded gate valves, which are used to connect the valve to an application.

Common Uses in Industry

Gate valves are commonly used in industrial applications due to their ability to provide straight-through flow and minimal pressure loss. They are frequently employed in the oil and gas industry, water treatment plants, and chemical processing facilities. Additionally, gate valves are useful in regulating the flow of abrasive and corrosive fluids, making them ideal for harsh industrial environments.

Signs You Need Gate Valve Repair

Gate valves play a critical role in controlling the flow of liquids in a variety of industrial and commercial settings. However, over time, these valves may develop issues that require immediate attention. Recognizing the signs that indicate your gate valve needs repair can help prevent costly downtime and potential safety hazards.

Detection of Leaking Gate Valve

One of the most obvious signs that a gate valve needs repair is the presence of leaks. Leakage around the valve body or stem is a clear indication that the valve is not functioning properly. It is important to address leaking gate valves promptly to prevent further damage to the system and ensure the safety of personnel working in the vicinity.

Operational Issues

Another sign that your gate valve may need repair is operational issues. If you notice that the valve is not opening or closing smoothly, or if it is getting stuck in a partially open or closed position, it is likely that the valve requires attention. These operational issues can lead to inefficiencies in the system and may indicate internal damage or blockages that need to be addressed through repair or maintenance.

Wear and Corrosion

Wear and corrosion are common issues that can affect the performance of gate valves over time. Visual inspection of the valve body, stem, and other components can reveal signs of wear and corrosion. This may manifest as pitting, erosion, or scaling on the surfaces of the valve. Addressing wear and corrosion through timely repair or replacement of affected components is essential to maintaining the integrity and functionality of the gate valve.

By being attentive to these signs, you can take proactive steps to address gate valve issues before they escalate into more significant problems. Regular inspection and maintenance can help prolong the lifespan of gate valves and ensure the reliable operation of fluid control systems.

Preparing for Gate Valve Repair

Valve repair requires meticulous preparation to ensure safety and effective execution. Prior to initiating any repair work, adherence to safety protocols, acquiring necessary tools and materials, and proper valve isolation and de-pressurization are imperative.

Safety Protocols

Before commencing any valve repair, it is crucial to prioritize safety. Ensure that the work area is clear of any obstructions, and that proper personal protective equipment (PPE) is worn at all times. This includes safety goggles, gloves, and appropriate footwear. Additionally, it is essential to review and adhere to all relevant safety procedures and guidelines to mitigate potential hazards.

Necessary Tools and Materials for Gate Valve Repair

Having the appropriate tools and materials readily available is essential for a successful gate valve repair. Some of the necessary tools include adjustable wrenches, pipe wrenches, valve packing, replacement gaskets, and a pipe cutter. Additionally, materials such as lubricants, cleaning solvents, and replacement parts should be procured in advance to facilitate a seamless repair process.

Valve Isolation and De-pressurization

Proper isolation and de-pressurization of the valve are critical steps to ensure a safe working environment. Identifying and closing the isolation valves to stop the flow of media through the valve is the initial step. Following this, the valve should be de-pressurized by carefully releasing any residual pressure within the system. This can be achieved by opening the valve and allowing the media to dissipate in a controlled manner. It is essential to verify that the valve is completely depressurized before initiating any repair work.

By adhering to these preparatory measures, the gate valve repair process can be executed efficiently and safely, setting the stage for a successful outcome.

Step-by-Step Gate Valve Repair Guide

How to Repair a Gate Valve

Before delving into a gate valve repair process, it is fundamental to understand the intricate details of each step involved in the procedure. From disassembling the gate valve to reassembling and testing it, each stage requires meticulous attention and precision to ensure the optimal functioning of the valve. In the following sections, we will comprehensively guide you through the entire process, covering disassembly, component inspection, part cleaning and repair, and finally, reassembly and testing of the gate valve.

Disassembling the Gate Valve

When embarking on a gate valve repair, the initial step is to carefully disassemble the valve. Begin by shutting off the main water supply to the valve and relieving any residual pressure. Next, remove the valve bonnet and unscrew the stem nut from the stem. Then, proceed to dismantle the stem and gate from the valve body. Ensure coherence in arranging and labeling each removed part to facilitate effortless reassembly.

Inspecting Valve Components

Once the gate valve is disassembled, a thorough inspection of its components is imperative to identify any signs of wear, damage, or corrosion. Examine the gate, seats, stem, and other relevant parts for cracks, erosion, or any other irregularities. Additionally, carefully assess the valve body and bonnet for any signs of leakage or structural compromise that may warrant further repair or replacement.

Cleaning and Repairing Valve Parts

After inspecting the valve components, cleaning is essential to remove any accumulated debris, rust, or mineral deposits. Utilize appropriate cleaning agents and tools to ensure thorough cleansing without causing damage to the valve parts. In cases where repair is necessary, address any identified issues such as seat or stem damage, using suitable techniques and materials to restore optimal functionality to the valve components.

Reassembling and Testing the Valve

Once the valve components have been cleaned and repaired, the reassembly process can commence. Carefully reinsert the gate, stem, and other parts into the valve body, ensuring proper alignment and tightness. Subsequently, reattach the stem nut, bonnet, and any additional components, following the reverse order of disassembly. Upon completion of reassembly, perform a rigorous testing procedure to verify the efficacy of the repair, including checks for leakage, smooth operation, and overall functionality of the gate valve.

Professional Tips for Effective Gate Valve Repair

Gate valves are crucial components in various industries, but they can encounter issues requiring repair to ensure smooth operations. Understanding common problems and implementing effective repair strategies is essential for maintaining the functionality and integrity of gate valves.

Troubleshooting Common Problems

Gate Valve Fails to Close

A common issue with gate valves is the failure to close properly due to sediment buildup inside the valve body. Prolonged full opening can lead to the accumulation of dirt, obstructing the valve’s closure. To troubleshoot this problem, it is crucial to inspect the interior of the valve for sediment deposits and clean them thoroughly. Flushing the valve with a suitable cleaning solution can help remove the buildup and restore proper functionality.

Gate Valve Seized Open

In some cases, a gate valve may become seized in an open position, preventing it from closing as required. This can occur due to the accumulation of debris or corrosion in the valve’s mechanism. Conducting a comprehensive inspection of the valve components and addressing any obstructions or corrosion is essential to resolve this issue. Applying lubricants or rust inhibitors can aid in freeing the seized components and restoring the valve’s operation.

Gate Valve Does Not Open

When a gate valve fails to open, it can disrupt the flow of media within the system. This issue may arise from an obstruction within the valve body or a malfunctioning operating mechanism. Thoroughly examining the internal components of the valve and addressing any blockages or mechanical faults is crucial for resolving this issue. Lubricating the moving parts and ensuring smooth operation of the valve’s handle or actuator can facilitate the opening of the gate valve.

Gate Valve Leaking from Stem

Leakage from the stem of a gate valve can compromise the integrity of the entire system. This issue is often attributed to damaged or worn-out stem seals. Inspecting the stem seals and replacing any damaged or deteriorated seals is essential for preventing leakage. Additionally, assessing the alignment and condition of the stem components can help mitigate stem-related leaks and ensure a reliable seal.

Ensuring a Quality Seal

Achieving a reliable and durable seal is paramount for the efficient functionality of gate valves. Proper installation of the valve components, including the gate, seat, stem, and gaskets, is crucial for ensuring a quality seal. Regular inspection and maintenance of the sealing elements can help prevent leaks and enhance the overall performance of gate valves.

Longevity and Maintenance Tips

Maintaining the longevity of gate valves requires proactive maintenance practices. Implementing a regular inspection schedule to identify potential issues, such as corrosion, wear, or fluid contamination, is essential for preserving the operational lifespan of gate valves. Additionally, adhering to appropriate lubrication and cleaning regimens can contribute to the sustained performance and longevity of gate valves.

10 Important Reasons for Gate Valve Repair

- Prevent Leakage: Repairing a gate valve can prevent leakage and potential damage to the surrounding area.

- Ensure Proper Functionality: A repaired gate valve ensures proper functionality and efficient operation within the system.

- Extend Lifespan: Regular repairs can extend the lifespan of the gate valve, reducing the need for premature replacement.

- Maintain System Integrity: By repairing a gate valve, the overall integrity of the system is maintained, preventing potential failures.

- Optimize Performance: Well-maintained gate valves contribute to the optimized performance of the entire system.

- Prevent Contamination: Repairing a gate valve helps prevent contamination of the fluid or gas being controlled by the valve.

- Comply with Regulations: Properly maintained gate valves ensure compliance with industry regulations and standards.

- Reduce Downtime: Regular repairs minimize the risk of unexpected downtime due to valve malfunctions.

- Minimize Costs: Timely repairs can minimize long-term maintenance and replacement costs associated with gate valves.

- Enhance Safety: Maintaining and repairing gate valves enhances the overall safety of the system and the surrounding environment.

Understanding Gate Valve Repair Costs

Gate valve repair costs can vary depending on several factors. Understanding these factors and exploring cost-saving strategies can help in making informed decisions.

Factors Affecting Gate Valve Repair Costs

- Valve Type and Quality: The cost of repairing a gate valve can be influenced by the type and quality of the valve itself. Different materials and designs can affect the overall repair expenses.

- Extent of Damage: The extent of damage to the gate valve will directly impact the repair costs. Minor repairs may be more affordable, while extensive damage could result in higher expenses.

- Labor Charges: If hiring a professional for the repair, labor charges will contribute significantly to the overall repair costs. Location and complexity of the repair can also affect the labor charges.

- Additional Repairs or Replacements: Any additional components that require repairs or replacements alongside the gate valve can add to the total repair costs.

Cost-Saving Strategies

- Regular Maintenance: Implementing a routine maintenance schedule for gate valves can help in early detection of potential issues, reducing the need for costly repairs.

- Professional Inspection: Periodic inspection by a qualified technician can identify any minor problems before they escalate into major repair issues, ultimately saving on repair costs.

- Quality Parts and Materials: When replacing components during repairs, investing in high-quality parts and materials can lead to longer-term cost savings by reducing the frequency of repairs.

- DIY Repairs: For minor repairs, consider undertaking the repairs independently if you have the necessary skills and expertise, thus minimizing labor costs.

By understanding the factors influencing repair costs and implementing cost-saving strategies, individuals and businesses can effectively manage gate valve repair expenses.

Choosing the Right Gate Valve Repair Service

Certifications and Qualifications

Before selecting a gate valve repair service, it’s crucial to consider their certifications and qualifications. Look for service providers that hold certifications from reputable organizations such as the American Petroleum Institute (API) or the International Organization for Standardization (ISO). These certifications indicate a commitment to quality and adherence to industry standards. Additionally, ensure that the technicians performing the repairs are certified and possess the necessary training and expertise to handle gate valve maintenance and repairs.

Experience with Specific Valve Types

Another essential factor to consider when choosing a gate valve repair service is their experience with specific valve types. Gate valves come in various designs and materials, each requiring specific repair and maintenance techniques. Look for a service provider that has a proven track record of working with the type of gate valves installed in your facility. Whether it’s rising stem, non-rising stem, wedge, or knife gate valves, the repair service should demonstrate a deep understanding of the intricacies of each valve type to ensure effective and long-lasting repairs.

Comparing Gate Valve Repair Service Providers

When comparing gate valve repair service providers, consider aspects such as response time, availability of emergency services, and the overall reputation in the industry. Evaluate the service provider’s response time to maintenance requests, especially in critical situations that require immediate attention. Additionally, inquire about their availability for emergency repairs outside of regular working hours. Furthermore, seek feedback from other industry professionals and compare reviews and testimonials to gain insights into the service provider’s track record and customer satisfaction levels. By carefully weighing these factors, you can make an informed decision when selecting the right gate valve repair service for your specific needs.

Conclusion for Gate Valve Repair

In conclusion, creating and optimizing cornerstone content is crucial for improving the SEO of your website. By focusing on comprehensive and informative articles about important topics, you can enhance your chances of ranking for competitive keywords. Implementing a strong internal linking structure that emphasizes the prominence of your cornerstone content will further boost its visibility and authority in search engine results. Consistently updating and maintaining these cornerstone articles will contribute to the overall success of your SEO strategy.