Pneumatic Solenoid Valves: Essential Guidelines for Efficient Operation

Introduction

Understanding the nature of industrial equipment and how it contributes to the overall efficiency of your system is key to optimizing performance. One such essential piece of hardware is the pneumatic solenoid valve. A vital part of numerous mechanical and industrial applications, the importance of this versatile equipment cannot be overstated. This blog post will address all your questions and provide valuable information on this subject.

What is a Pneumatic Solenoid Valve?

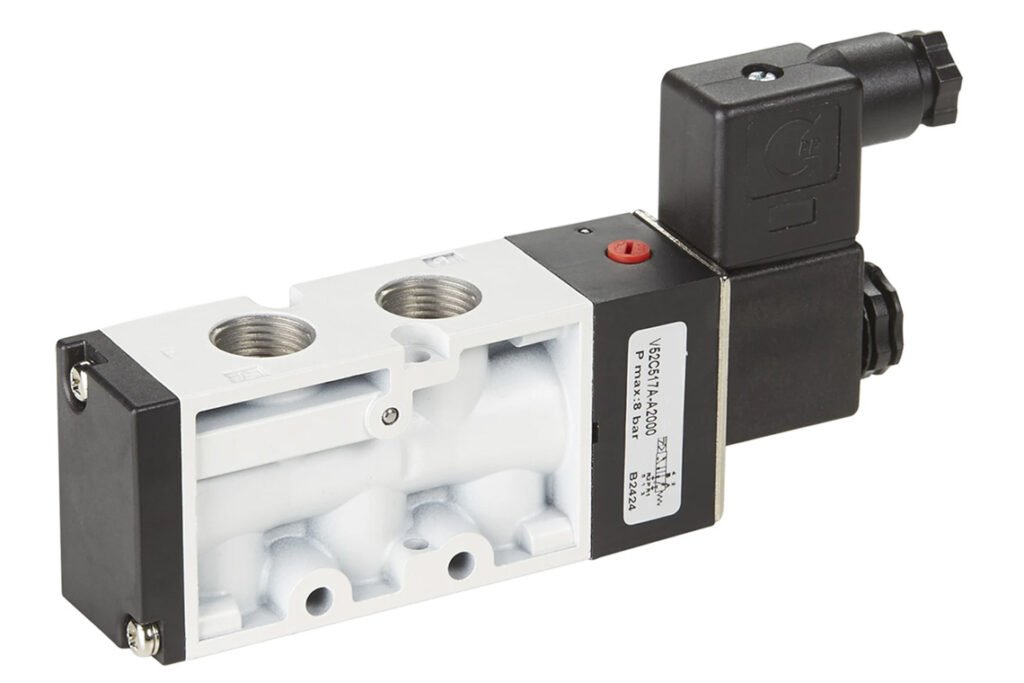

In the realm of industrial machinery and systems, a pneumatic solenoid valve plays a pivotal role. At its core, this device is a switch that dictates the movement of compressed air within mechanical and industrial systems.

A pneumatic solenoid valve converts electric signals into actions within a pneumatic system, like all other solenoid valves. This conversion empowers the device to control various pneumatically operated components such as actuators and cylinders, thus facilitating a seamless, automatic operation. The efficiency with which these valves can control the flow of air is paramount to the performance of the overall system. By understanding the role and function of a these valves, you can better grasp its impact on your industrial processes.

Image Credit: no.rs-online.com

Variety and Specifications of Pneumatic Solenoid Valves

The landscape of pneumatic solenoid valves is vast, with numerous types available to cater to a wide array of applications. The two primary categories that these valves fall under are direct acting valves and pilot operated valves. The key differentiator lies in their design and functionality.

Direct acting valves are engineered for systems with lower flow rates and pressures. This makes them a suitable choice for small-scale operations or systems with minimal requirements. Conversely, pilot operated valves are designed to handle higher flow rates and pressures, which are common in large-scale industrial processes.

In addition to the type of operation, other specifications differentiate one solenoid valve from another. These specifications include the port size, which is the diameter of the port through which the air flows. Pressure range is another crucial factor that signifies the minimum and maximum pressure levels the valve can handle. Another parameter to consider is the valve’s voltage requirement, which impacts the overall energy consumption.

The flow rate specification indicates the volume of air the valve can handle per unit of time. Lastly, pneumatic solenoid valves can be either normally closed, where the default state of the valve is closed, or normally open, where the valve remains open unless activated.

In essence, the broad spectrum of pneumatic solenoid valves in terms of variety and specifications ensures that there’s a suitable option for virtually any application. It’s essential, however, to match these specifications with your system’s needs to guarantee optimal performance.

How does a Pneumatic Solenoid Valve Work?

The functionality of a pneumatic solenoid valve is determined by the interaction between two main components: the solenoid and the valve itself. The solenoid, also known as an electromagnetic coil, is responsible for generating a magnetic field. When an electric current is supplied to the solenoid, this magnetic field is activated, initiating the movement of a plunger nestled within the coil. This movement of the plunger is the catalyst for the opening or closing of the valve.

The status of the valve, whether open or closed, controls the passage of compressed air within the system. This regulation of air flow is what allows the pneumatic solenoid valve to operate different pneumatically driven parts like actuators and cylinders. It’s this key role in controlling the flow of air that determines the performance of the overall system. The efficient functioning of the valve depends on the successful interaction of the solenoid and the valve, illustrating the intricate balance required for optimal operation of a pneumatic solenoid valve.

Key Applications of Pneumatic Solenoid Valves

Manufacturing Industry

In manufacturing, pneumatic solenoid valves play a critical role in automation processes. They are commonly used to control the movement of robotic arms, sorting equipment, and assembly lines. This precise control of air flow allows for efficient and accurate operation. Moreover, they significantly reduce manual intervention, resulting in reduced labor costs and human error. Their consistent performance guarantees product uniformity and quality, contributing to higher productivity and operational efficiency.

Medical Equipment

Pneumatic solenoid valves are integral to the functioning of many medical devices. For instance, they are found in ventilators and anesthesia machines, controlling the flow of air and oxygen to the patient. Moreover, these valves are vital in equipment such as nebulizers, providing precise regulation of medication delivery. In complex diagnostic machinery like CT scanners, pneumatic solenoid valves ensure precise air control, affecting image clarity and accuracy.

Food and Beverage Industry

These valves are widely used in the food and beverage industry. They are key in processes such as filling and packaging, where they help to control the flow of liquids, ensuring accurate portioning and sealing. Additionally, they’re utilized in systems like beverage dispensers, enabling consistent pressure and flow rate for optimal serving. They’re also found in food processing machinery, managing the use of ingredients and ensuring sanitary conditions by regulating steam and hot water flow.

Heating, Ventilation, and Air Conditioning (HVAC) Systems

Pneumatic solenoid valves are crucial to the regulation of temperature and humidity in HVAC systems. By controlling the flow of cool or heated air, they help maintain a comfortable indoor environment. Their reliability and efficient operation make them indispensable in both residential and commercial HVAC systems. This, coupled with their long lifespan and low maintenance requirements, makes them a cost-effective solution for HVAC control.

Automotive Industry

In the automotive industry, these valves are used in applications like emission controls and automatic transmission systems. They aid in managing the flow of fluids and gases, contributing to optimal vehicle performance. In fuel injection systems, they help to precisely regulate the fuel-air mixture for combustion, ensuring peak engine efficiency. Additionally, they play a role in air conditioning systems, managing the flow of refrigerant to maintain the desired temperature.

Mining Industry

In the harsh conditions of mining operations, the durability of pneumatic solenoid valves is key. They’re used to control air-powered tools and equipment, increasing efficiency and safety. Particularly in drilling and excavation processes, the valves ensure consistent and safe operation of machinery, mitigating potential hazards. Additionally, they regulate the flow of pressurized air to pneumatic pumps and blasting equipment, enhancing overall productivity.

Water and Wastewater Treatment

Lastly, these valves are utilized extensively in water and wastewater treatment facilities. They assist in the regulation of air flow in processes such as filtration, disinfection, and sludge treatment, playing a critical role in the purification of water resources. In addition, pneumatic solenoid valves ensure precise control in processes like chemical dosing and pH control.

This helps maintain the health of the ecosystem and guarantees the quality of treated water. For example, in a water treatment plant, pneumatic solenoid valves are used to accurately control the introduction of disinfectants into the water supply, eliminating harmful bacteria and ensuring water safety for consumers.

Image Credit: vortexglobal.com

Leading Brands Manufacturing Pneumatic Solenoid Valves

The pneumatic solenoid valve market is teeming with reputable manufacturers, each renowned for their high-quality products designed to cater to a range of industrial needs. Among the front-runners in this field are brands such as Parker, a company known for its innovative engineering and wide variety of solenoid valves. Another notable name in this realm is SMC Corporation, a global leader in pneumatic control engineering.

Adding to the list of top manufacturers is Festo, a company celebrated for their focus on automation technology and technical education solutions. Their range of solenoid valves is known to be highly durable and efficient.

ASCO is another established brand in the industry, offering an extensive array of solenoid valves designed to handle various flow rates and pressures. Their products are known for their reliability and long-lasting performance.

Finally, we have Norgren, a company with a broad portfolio of high-performance pneumatic and fluid control solutions, including solenoid valves. Their products are widely utilized across multiple industries thanks to their quality and versatility.

Each of these manufacturers offers a diverse range of pneumatic solenoid valves, making it possible for users to find a valve that aligns perfectly with their specific operational requirements. When selecting a valve, always remember to take into account the specifications and features of the product to ensure it will deliver optimal performance within your system.

Pros and Cons of Pneumatic Solenoid Valves

As with any piece of industrial equipment, pneumatic solenoid valves come with their own sets of advantages and disadvantages. It’s essential to understand these factors to make an informed decision about whether this valve is the right fit for your system.

Advantages of Pneumatic Solenoid Valves

Pneumatic solenoid valves offer a number of benefits, the most significant being their efficiency and reliability. These valves are renowned for their rapid response time, allowing for precise control of compressed air within the system. Their robust construction ensures their durability, even in harsh working conditions.

Given their operational mechanism, they require minimal maintenance, reducing associated downtime and costs. They are also relatively simple to install, thanks to their straightforward design and function. They are versatile enough to be used in a variety of industries, from manufacturing to HVAC systems and more. Additionally, their compact size allows for easy integration into systems with space constraints.

Disadvantages of Pneumatic Solenoid Valves

Pneumatic solenoid valves also come with a few drawbacks that must be considered. Their dependency on electricity means that they’re susceptible to power failures, which could disrupt system operation. While they excel in controlling the flow of compressed air, they are not universally compatible with other types of fluids, potentially limiting their utility in certain applications.

Pneumatic solenoid valves typically work within a specified pressure range, and any deviation beyond this range can cause them to malfunction. Finally, while they are typically low-maintenance, any necessary repairs or replacements can be expensive, especially for larger, high-pressure valves. Recognizing these pros and cons will provide a more holistic view of whether a solenoid valve is the ideal choice for your specific operational needs and conditions.

Image Credit: control.com

Frequently Asked Questions About Pneumatic Solenoid Valves

How do the pros and cons of pneumatic solenoid valves compare to other types of control valves, such as electrically actuated or manual valves?

Pneumatic solenoid valves offer faster response times and require less maintenance compared to manual valves. However, unlike electrically actuated valves, they do require a constant supply of compressed air to function. This means they may not be the best option for applications where an uninterrupted air supply cannot be guaranteed. Also, in environments prone to power fluctuations or outages, the performance of these valves may be impacted.

Nonetheless, with the appropriate setup, including a backup air compressor, these issues can be mitigated. It’s important to carefully consider the specific demands of your application before selecting a valve type. In making your decision, think about your operational environment, air supply, and response time needs. Reach out to a reputable supplier who can guide you to choose the right type of valve for your specific application.

In conclusion, while pneumatic solenoid valves offer considerable benefits, understanding the specific requirements of your system is essential to making the most appropriate valve selection. Always consult with an experienced supplier for a decision that serves both your immediate needs and long-term operational success.

Which manufacturer brands offer high-quality pneumatic solenoid valves for industrial applications?

Numerous manufacturers produce high-quality pneumatic solenoid valves for industrial applications, including Parker Hannifin, SMC Corporation, and ASCO. Consulting a comprehensive resource like Direct Industry’s online catalogue can help you explore a wide array of brands and make an informed choice.

Also, keep in mind that each manufacturer may offer unique features or specific benefits that could align well with your operational needs. Hence, careful comparison and evaluation of multiple options will likely result in the best selection. It is crucial to understand the specifications, certifications, and reputation of each manufacturer. Do not hesitate to ask for recommendations and read customer reviews to make a comprehensive decision.

Ultimately, by taking the time to understand the distinct advantages and limitations of pneumatic solenoid valves and comparing various manufacturer options, you can effectively identify the best solution for your specific industrial application. Remember, the key to a wise decision is in-depth research and consulting with industry professionals.

Are there any environmental or safety considerations when working with pneumatic solenoid valves?

Yes, while pneumatic solenoid valves are generally safe and environmentally friendly, certain safety and environmental precautions should be considered. They can release compressed air into the environment during operation, which should be taken into account when dealing with sound-sensitive environments, as this could create noise pollution.

Additionally, the release of compressed air could also potentially displace other gases in the area, so appropriate ventilation is crucial. Furthermore, if the valve system malfunctions or is improperly handled, it could result in pressure build-up and possible injuries, thus emphasizing the need for routine maintenance and safety measures.

Can pneumatic solenoid valves be integrated with programmable logic controllers (PLCs) and other control systems?

Absolutely! Pneumatic solenoid valves are typically designed with compatibility in mind and can indeed be integrated with various control systems, including PLCs. This flexibility allows for comprehensive control and management of industrial systems, enabling greater efficiency and automation within operations. Additionally, integrating these valves with PLCs can facilitate real-time monitoring and remote control capabilities, enhancing your operational reliability and responsiveness.

In conclusion, understanding the features, functionality, and compatibility of pneumatic solenoid valves, coupled with diligent selection and mindful safety measures, ensures efficient integration with your existing control systems. This knowledge allows you to fully harness the potential of these robust and versatile components in your industrial application, promoting productivity and system efficiency.

How does the power supply voltage affect the operation of a pneumatic solenoid valve?

The power supply voltage is a critical factor in the operation of a pneumatic solenoid valve, as it controls the opening and closing of the valve. Incorrect voltage can cause a valve to not actuate properly, resulting in operational inefficiency or even system failure. Hence, it’s essential to ensure that the power supply voltage matches the manufacturer’s specifications for the solenoid valve.

Any deviations, either over-voltage or under-voltage, may lead to premature valve failure, compromising the efficiency of your industrial system. To prevent this, it’s advised to regularly check your power supply and implement necessary safety measures. Also, consider incorporating a voltage regulator into your system to ensure a steady supply within the recommended voltage range.

What is the typical lifespan of a pneumatic solenoid valve?

The lifespan of a pneumatic solenoid valve largely depends on its usage, quality, maintenance and operational conditions. In general, with proper maintenance and care, these valves can function effectively for several years. However, exposure to extreme conditions or corrosive materials may reduce their longevity. Therefore, regular inspection and timely replacement of worn-out parts can significantly enhance the lifespan and performance of these valves.

Also, implementing a predictive maintenance strategy, such as monitoring for irregularities in valve operation, can help preempt potential problems, saving you downtime and costs in the long run. Always remember, investing time and resources in regular maintenance can be highly beneficial to your overall system performance.

Can a pneumatic solenoid valve be used for both air and liquid control systems?

Yes, pneumatic solenoid valves are designed to control the flow of both air and liquid. However, the specific suitability will depend on the design and specifications of the valve, along with the characteristics of the liquid involved. For example, certain valves might be better suited for handling corrosive liquids, while others could be more suitable for high-temperature fluids.

Always make sure to match the valve’s specifications with the nature and demands of your particular application. It’s also crucial to consider factors like flow rate and pressure requirements of your system when selecting a valve. Choosing the right valve not only ensures smooth operation but also contributes to the durability of your system.

What is a 12v pneumatic solenoid valve and what is its usage areas?

A 12v pneumatic solenoid valve refers to a valve that operates at 12 volts, and it’s predominantly used in various industrial and automotive applications. It can control air, water, and even fuel systems, making it highly versatile for many areas of usage. Given its wide-ranging utility, the 12v pneumatic solenoid valve has been a favored choice in industries ranging from automotive to manufacturing.

By ensuring careful selection based on specific requirements, you can effectively leverage its potential for diverse applications. Such careful selection will allow you to optimize performance, longevity, and overall system efficiency. Plus, you can better navigate operational challenges that may arise with its use.

Design considerations for integrating pneumatic solenoid valves into a system

- Designing an industrial system that includes pneumatic solenoid valves requires thoughtful planning and careful selection of components.

- The system’s flow rate and pressure requirements should be one of the first considerations.

- Direct acting valves are suitable for systems with lower flow rates and pressures.

- Pilot operated valves are designed to handle higher flow rates and pressures.

- The electrical power supply is another crucial factor.

- The voltage should be compatible with the solenoid valve’s requirements.

- Consider incorporating a voltage regulator to maintain a consistent supply within the recommended range and prevent premature valve failure.

- Pneumatic solenoid valves can be integrated with various control systems, including PLCs, which can provide real-time monitoring and remote control capabilities.

- The control system should be designed to mitigate any potential issues caused by power fluctuations or outages.

- Maintenance accessibility should be incorporated in the design.

- The location of the valve should allow for easy access for inspection and routine maintenance.

- Provision for replacement of worn-out parts should be included in the design.

- Safety is paramount.

- The system design should consider potential sound-sensitive environments due to the release of compressed air from the valve and include appropriate ventilation.

- Safety measures should be put in place to avoid pressure build-up and possible injuries due to valve system malfunction or improper handling.

- By keeping these considerations in mind, a system can be designed that not only integrates efficiently with pneumatic solenoid valves but also optimizes their functionality and lifespan.

Conclusion: Making the Most of Pneumatic Solenoid Valves

The role of pneumatic solenoid valves in industrial and mechanical systems is significant and varied. With a deep understanding of their operations, types, and specifications, you are better positioned to make the right choice of valve for your specific needs.

Be aware of the operational requirements of your system, including flow rate and pressure, when making your selection. Weigh the benefits and drawbacks of each valve, keeping in mind the unique conditions of your operational environment. Always refer to the manufacturer’s guidelines for optimum use and maintenance of the valve. When chosen wisely and maintained appropriately, a pneumatic solenoid valve can significantly improve your system’s efficiency and lifespan.

It’s not just about picking any valve, but about finding the valve that best suits your system’s demands. Armed with this knowledge, you are now ready to harness the full potential of pneumatic solenoid valves in your operations.