Using Globe Valves for Efficient Industrial Applications

Table of Contents

ToggleIntroduction

Globe valves are essential components in various industrial applications, providing efficient control of fluid flow. Understanding the key characteristics of globe valves is crucial for ensuring optimal performance and reliability in industrial processes. In this blog post, we will delve into the important features and benefits of globe valves, shedding light on their significance in industrial settings.

Whether you are an engineer, maintenance professional, or simply curious about industrial valves, this comprehensive guide will equip you with the knowledge needed to appreciate the role of globe valves in ensuring efficient operations.

What are Globe Valves?

Globe valves are essential components widely used in industrial applications, known for their efficient control of flow. These valves are designed to regulate the flow of a fluid in a pipeline, ensuring precise control over the rate of flow.

Definition and Function

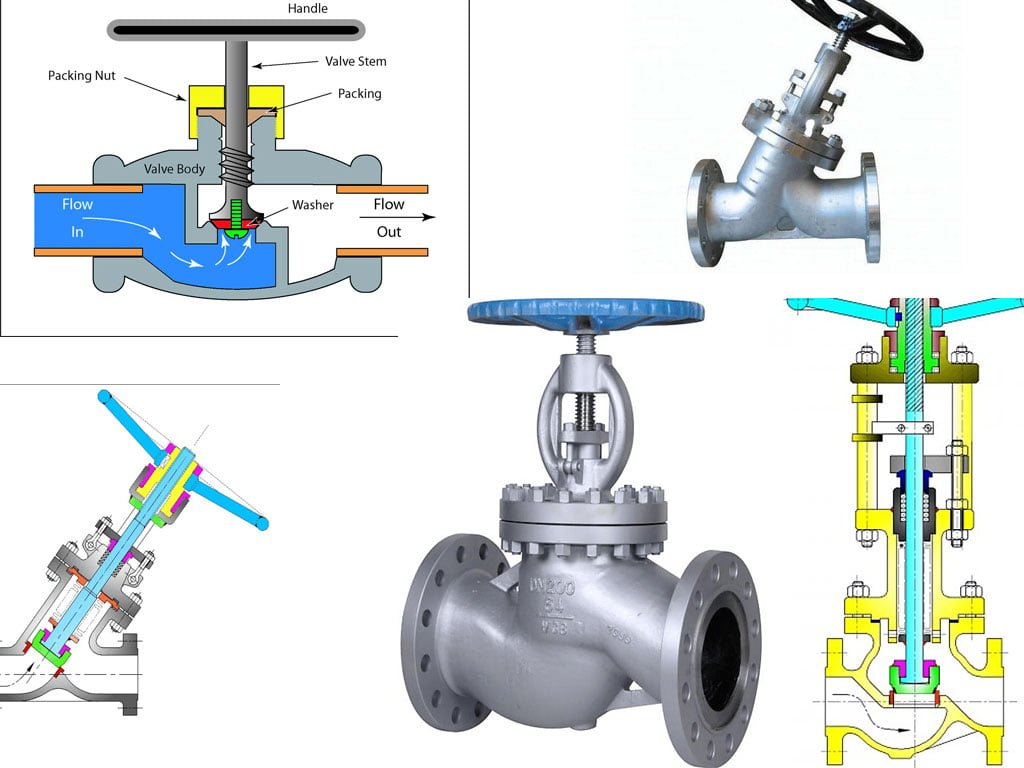

Globe valves operate by moving a disk up and down against the flow of the fluid. This motion regulates the flow by opening and closing the passage inside the valve. The spherical shape of the valve body and the internal baffle distinguish it from other types of valves.

Types of Globe Valves

- Bolted Bonnet Globe Valves: These valves feature a bonnet connected to the body using bolts, allowing for easy maintenance and repair.

- Pressure Seal Bonnet Globe Valves: Suitable for high-pressure applications, these valves provide a seal through internal pressure.

Globe valves are available in various designs to suit specific operational requirements, making them versatile choices for a wide range of industrial settings.

Key Characteristics of Globe Valves

Globe valves are crucial components in industrial applications, designed with key characteristics that ensure efficient and precise operation. Understanding the various features of globe valves is essential for optimizing their performance in industrial settings.

Body Design and Construction

The body of a globe valve is typically structured with a spherical shape, which allows for efficient handling of flow regulation and pressure control. The design includes a streamlined passage that enables smooth fluid flow, minimizing turbulence and pressure drop within the valve. Additionally, the construction of these valves often involves durable materials such as stainless steel or cast iron, ensuring robustness and resistance to corrosion, thus enhancing longevity in industrial environments.

Valve Disc and Seat

The valve disc and seat play a pivotal role in controlling the flow of fluid within the globe valve. The disc, positioned perpendicular to the flow path, can be raised or lowered to regulate the flow. The seat forms a tight seal with the disc, preventing leakage and ensuring precise control over the fluid passing through the valve. This design feature allows for reliable shut-off and smooth modulation of flow, supporting the efficient operation of the valve.

Stem and Bonnet Assembly

The stem and bonnet assembly in a globe valve contributes to its operational reliability and maintenance ease. The stem serves as the conduit for transferring the motion from the actuator to the disc, enabling precise control of fluid flow. Additionally, the bonnet provides a protective enclosure for the stem and the critical internal components, safeguarding them from environmental factors, thus ensuring the integrity and longevity of the valve assembly.

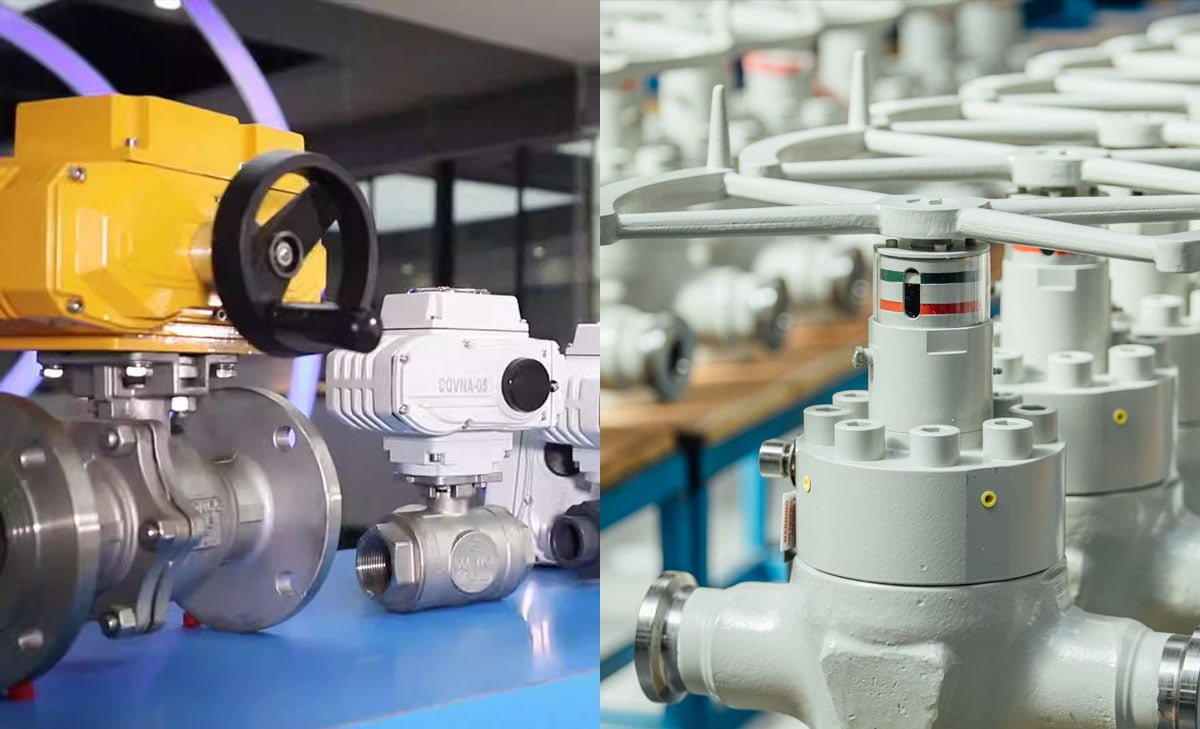

Actuation Methods

Globe valves can be actuated using various methods, including manual hand wheels, pneumatic actuators, or electric motors. Manual actuation offers simplicity and control, while pneumatic and electric actuation provides automated and remote operation, allowing for seamless integration into industrial control systems. The versatility in actuation methods enhances the adaptability of these valves to different industrial processes and control requirements.

Flow Control and Pressure Drop

The design of globe valves facilitates precise flow control and offers the ability to regulate pressure drop within the system. By adjusting the position of the valve disc, operators can manage the flow rate and optimize the pressure drop across the valve, ensuring efficient and stable operation within industrial systems. This feature is crucial for maintaining process parameters and enhancing system performance.

Understanding these key characteristics of globe valves is essential for selecting, installing, and maintaining these components in industrial applications, ensuring optimal performance and reliability in fluid handling processes.

Materials and Applications

Globe valves are vital components in industrial applications, playing a crucial role in regulating and controlling the flow of various fluids. The effectiveness and efficiency of globe valves can be greatly influenced by the materials used in their construction and their specific applications within different industrial environments.

Suitable Materials for Different Environments

When it comes to selecting suitable materials for globe valves, it’s essential to consider the specific environmental conditions in which they will operate. For instance, in environments where corrosive fluids are present, materials like stainless steel and alloy steels are preferred due to their corrosion-resistant properties. In high-temperature applications, materials such as carbon steel and forged steel are commonly utilized for their ability to withstand elevated temperatures without compromising structural integrity.

In contrast, for applications involving cryogenic fluids, materials like stainless steel with low thermal expansion are preferred to ensure optimal performance under extreme temperature conditions. Furthermore, in industries where cleanliness and hygiene are critical, such as pharmaceutical and food processing, these valves constructed from materials like stainless steel with smooth surface finishes are chosen to maintain the purity of the processed fluids.

Industrial Applications of Globe Valves

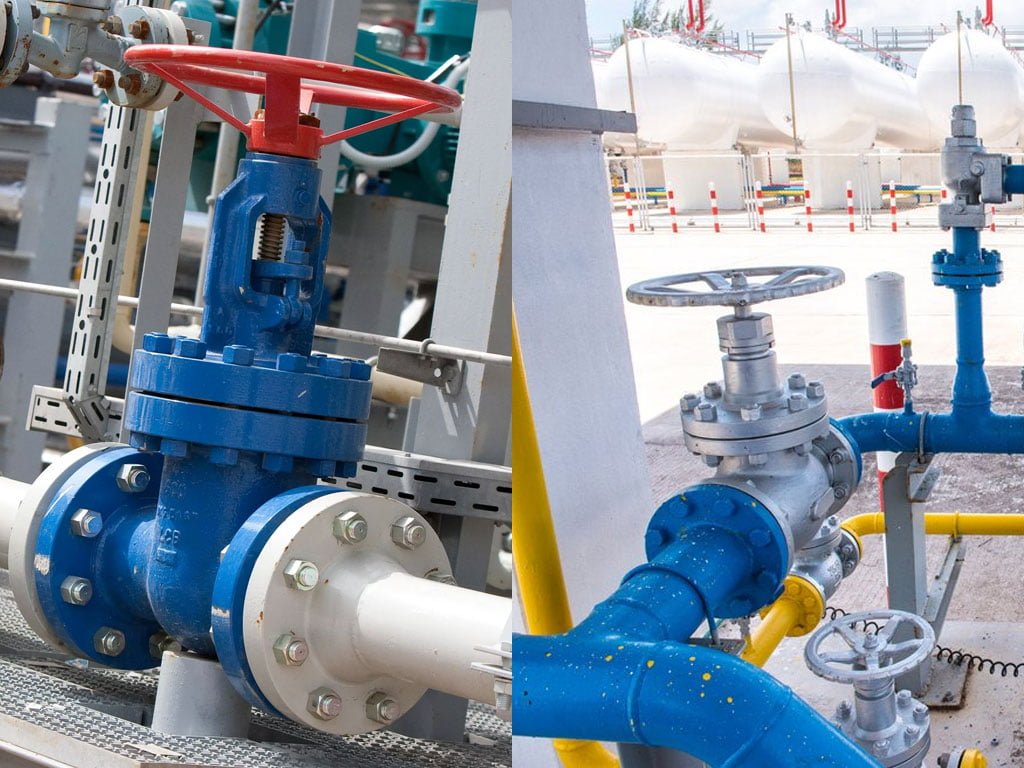

The versatility of globe valves makes them indispensable in a wide range of industrial applications. In the oil and gas industry, globe valves are extensively used for regulating the flow of crude oil, natural gas, and various petroleum products. Their ability to provide accurate flow control and tight shut-off makes them ideal for processes such as refining, pipeline distribution, and storage facilities.

Moreover, in power generation plants, globe valves play a crucial role in controlling the flow of steam, water, and other cooling fluids within boilers, turbines, and heat exchangers. Their ability to handle high-pressure and high-temperature conditions makes them well-suited for ensuring safe and efficient operation in such demanding environments.

In the chemical processing industry, globe valves are employed for managing the flow of corrosive chemicals, acids, and hazardous gases. The robust construction and diverse material options allow these valves to withstand the aggressive nature of these substances while offering precise control and reliability in critical processes.

In summary, selecting the appropriate materials for specific environmental conditions and understanding the diverse industrial applications of globe valves are essential considerations for ensuring their efficient performance and reliability in various industrial settings.

Advantages of Globe Valves

Globe valves offer several key advantages that make them a popular choice for various industrial applications. Their precise flow regulation, tight shutoff capability, and versatility in pressure and temperature make them highly efficient and reliable in controlling the flow of different types of fluids.

Precise Flow Regulation

Globe valves are well-known for their precise control over the flow of fluids. The design of the valve allows for fine adjustments, making it ideal for applications that require accurate flow regulation. This level of precision can be critical in industries where the proper management of fluid flow is essential for operational efficiency and safety.

Tight Shutoff Capability

One of the primary advantages of globe valves is their ability to provide a tight shutoff. When the valve is fully closed, it effectively stops the flow of fluid, preventing any leakage or seepage. This feature is particularly crucial in applications where containment of the fluid is a priority, such as in chemical processing or high-pressure systems.

Versatility in Pressure and Temperature

Globe valves exhibit exceptional versatility in handling varying pressure and temperature conditions. They can effectively manage high-pressure environments while also accommodating extreme temperature ranges. This flexibility makes these valves suitable for a wide range of industrial settings, where the operating conditions may fluctuate significantly.

In summary, the advantages of globe valves, including precise flow regulation, tight shutoff capability, and versatility in pressure and temperature, position them as a reliable choice for efficient fluid control in diverse industrial applications.

Considerations for Efficient Industrial Applications

Effective operation of globe valves in industrial applications depends on several critical considerations to ensure optimal performance and reliability.

Proper Sizing and Selection

When selecting globe valves for industrial applications, proper sizing is crucial. Choosing the right valve size and type ensures efficient flow control and prevents unnecessary pressure drops. Factors such as flow rate, pressure, and temperature must be carefully evaluated to determine the appropriate valve dimensions and specifications for the specific industrial process.

Maintenance and Service Requirements

Maintenance and service requirements play a vital role in the efficient operation of globe valves. Regular inspection, lubrication, and repair are essential to prevent performance degradation and extend the valve’s lifespan. Proper maintenance practices also contribute to minimizing downtime and optimizing the overall performance of industrial systems where these valves are employed.

Integration with Control Systems

The seamless integration of globe valves with control systems is imperative for efficient industrial applications. Incorporating these valves into automated control systems enables precise regulation of flow and pressure, enhancing operational efficiency and responsiveness to dynamic process conditions. Integration also facilitates real-time monitoring and adjustment, contributing to overall system reliability and performance.

Ensuring proper sizing and selection, addressing maintenance and service requirements, and integrating globe valves with control systems are critical considerations for achieving efficient and reliable performance in industrial applications.

Conclusion

In conclusion, globe valves play a crucial role in ensuring efficient and reliable industrial operations. Their key characteristics, including precise throttling capability, excellent shutoff functionality, and compatibility with high-pressure applications, make them essential components in various industries such as oil and gas, chemical processing, and power generation. Understanding these features and their benefits is vital for selecting the most suitable globe valves for specific industrial applications, ultimately contributing to enhanced operational efficiency and safety.